Page 103 - Turner 1st sem Practicals

P. 103

• Hold the tool at an angle of 55° to the face of the wheel. passing through gauge and cutting edges of the tool.

• Cutting point is carefully ground in a smooth wheel.

• Grind on left hand side of the tool.

• Finally lap the tool by applying oil stone on cutting

• Repeat the above procedure on the right side of the edges.

tool to get an included angle of 55° on the tool. Remember

• Grind 2° to 4° side clearance angle on each side of the • Avoid burning of the tool.

tool.

• The cutting edge should be visible during grinding.

• Finish all sides by using smooth grinding wheel. Check

the tool by centre gauge; there should not be any light

Skill sequence

Grinding a side cutting tool for machining steel

Objective : This shall help you to

• grind a right hand side cutting tool to machine steel.

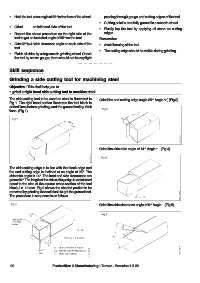

The side cutting tool to be used on steel is illustrated in Grind the end cutting edge angle 25°. Angle ‘x ’ (Fig 3)

Fig 1. The right hand portion illustrates the tool blank in n

dotted lines before grinding, and the ground tool by thick

lines. (Fig 1)

Grind the side rake angle of 14°. Angle . (Fig 4)

The side cutting edge is in line with the blank edge and

the end cutting edge is inclined at an angle of 25°. The

side rake angle is 14°. The front and side clearances are

ground 6°. The length of the side cutting edge is maintained

equal to the size of the square cross-section of the tool

blank, i.e. 12 mm. Fig 2 shows the shaded portion to be

removed by grinding the tool blank to get the ground tool.

The procedure in sequence is as follows.

Grind the side clearance angle of 6°. Angle (Fig 5)

90 Producltion & Manufacturing : Turner - Exercise 1.3.29