Page 115 - Turner 1st sem Practicals

P. 115

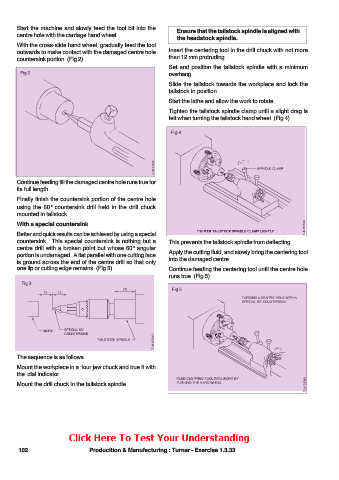

Start the machine and slowly feed the tool bit into the Ensure that the tailstock spindle is aligned with

centre hole with the carriage hand wheel.

the headstock spindle.

With the cross-slide hand wheel, gradually feed the tool

outwards to make contact with the damaged centre hole Insert the centering tool in the drill chuck with not more

countersink portion. (Fig 2) than 12 mm protruding.

Set and position the tailstock spindle with a minimum

overhang.

Slide the tailstock towards the workpiece and lock the

tailstock in position.

Start the lathe and allow the work to rotate.

Tighten the tailstock spindle clamp until a slight drag is

felt when turning the tailstock hand wheel. (Fig 4)

Continue feeding till the damaged centre hole runs true for

its full length.

Finally finish the countersink portion of the centre hole

using the 60° countersink drill held in the drill chuck

mounted in tailstock.

With a special countersink

Better and quick results can be achieved by using a special

countersink. This special countersink is nothing but a This prevents the tailstock spindle from deflecting.

centre drill with a broken point but whose 60° angular

portion is undamaged. A flat parallel with one cutting face Apply the cutting fluid, and slowly bring the centering tool

is ground across the end of the centre drill so that only into the damaged centre.

one lip or cutting edge remains. (Fig 3) Continue feeding the centering tool until the centre hole

runs true. (Fig 5)

The sequence is as follows.

Mount the workpiece in a four jaw chuck and true it with

the dial indicator.

Mount the drill chuck in the tailstock spindle.

102 Producltion & Manufacturing : Turner - Exercise 1.3.33