Page 51 - Turner 1st sem Practicals

P. 51

• Turn and change the position of pipe while sawing.

Do not cut too fast.

Caution : Avoid over tightening the pipe in the Cut very slowly and reduce pressure while

vice which may cause deformation. cutting through.

Skill Sequence

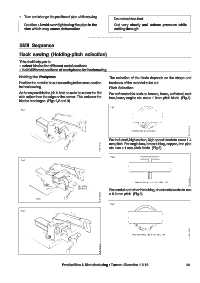

Hack sawing (Holding-pitch selection)

This shall help you to

• select blades for different metal sections

• hold different sections of workpieces for hacksawing.

Holding the Workpiece

The selection of the blade depends on the shape and

Position the metal to be cut according to the cross-section hardness of the material to be cut.

for hacksawing.

Pitch Selection

As far as possible the job is held so as to be cut on the flat For soft materials such as bronze, brass, soft steel, cast

side rather than the edge or the corner. This reduces the iron, heavy angles etc. use a 1.8mm pitch blade. (Fig 4)

blades breakages. (Figs 1,2 and 3)

For tool steel, high carbon, high speed steel etc. use a 1.4

mm pitch. For angle iron, brass tubing, copper, iron pipe

etc. use a 1 mm pitch blade. (Fig 5)

For conduit and other thin tubing, sheet metal work etc. use

a 0.8 mm pitch. (Fig 6)

Producltion & Manufacturing : Turner - Exercise 1.2.13 39