Page 136 - Turner 1st sem Practicals

P. 136

Skill sequence

Boring a drilled hole

Objectives : This shall help you to

• set the boring tool in the tool post

• bore the drilled hole to the required size

• check the hole with the help of a vernier caliper.

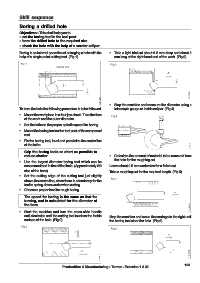

Boring is an internal operation of enlarging a hole with the • Take a light trial cut about 0.2 mm deep and about 8

help of a single point cutting tool. (Fig 1) mm long at the right hand end of the work. (Fig 3)

• Stop the machine and measure the diameter using a

To bore the hole the following procedure is to be followed. telescopic gauge or inside caliper. (Fig 4)

• Mount the workpiece in a four jaw chuck. True the face

of the work and the outer diameter.

• Set the lathe to the proper spindle speed for boring.

• Mount the boring tool on the tool post of the compound

rest.

• Fix the boring tool, level and parallel to the centre line

of the lathe.

Grip the boring tools as short as possible to

reduce chatter. • Calculate the amount of material to be removed from

the hole for the roughing cut.

• Use the largest diameter boring tool which can be

accommodated in the drilled hole. (Approximately 2/3 Leave about 0.5 mm undersize for a finish cut.

size of the bore) Take a roughing cut for the required length. (Fig 5)

• Set the cutting edge of the cutting tool just slightly

above the centre line, since there is a tendency for the

tool to spring downwards when cutting.

• Choose a proper feed for rough boring.

The speed for boring is the same as that for

turning, and is calculated for the diameter of

the bore.

• Start the machine and turn the cross-slide handle

anti-clockwise until the cutting tool touches the inside Stop the machine and move the carriage to the right until

surface of the hole. (Fig 2) the boring tool clear the hole. (Fig 6)

Producltion & Manufacturing : Turner - Exercise 1.3.39 123