Page 151 - Turner 1st sem Practicals

P. 151

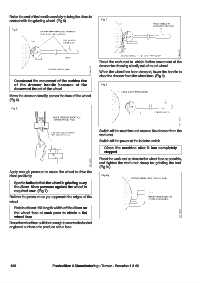

Raise the end of the handle carefully to bring the discs in

contact with the grinding wheel. (Fig 5)

Reset the work-rest to obtain further movement of the

dresser for dressing a badly out-of-round wheel.

When the wheel has been dressed, lower the handle to

clear the dresser from the wheel face. (Fig 8)

Counteract the movement of the sudden rise

of the dresser handle because of the

downward thrust of the wheel.

Move the dresser steadily across the face of the wheel.

(Fig 6)

Switch off the machine and remove the dresser from the

work-rest.

Switch off the power at the isolator switch.

Clean the machine after it has completely

stopped.

Reset the work-rest as close to the wheel face as possible,

and tighten the work-rest clamp for grinding the tool.

(Fig 8a)

Apply enough pressure to cause the wheel to drive the

discs positively.

Sparks indicate that the wheel is grinding away

the discs. More pressure against the wheel is

required now. (Fig 7)

Relieve the pressure as you approach the edges of the

wheel.

Retain atleast 1/2 length width of the discs on

the wheel face at each pass to obtain a flat

wheel face.

Dress the wheel face sufficient enough to remove the loaded

or glazed surface or to produce a true face.

138 Producltion & Manufacturing : Turner - Exercise 1.3.42