Page 95 - Turner 1st sem Practicals

P. 95

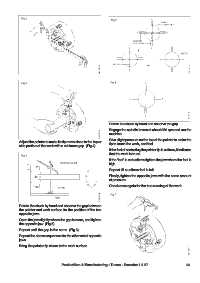

Rotate the chuck by hand and observe the gap.

Engage the spindle levers at about 250 rpm and run the

machine.

Give slight pressure on the top of the pointer to make the

Adjust the pointer to make its tip move close to the top or tip to touch the work, and feel.

side portion of the work with a minimum gap. (Fig 4)

If the feel of contacting the pointer tip is uniform, it indicates

that the work is trued.

If the ‘feel’ is not uniform tighten the jaw where the feel is

high.

Repeat till a uniform feel is felt.

Finally, tighten the opposite jaws with the same amount

of pressure.

Check once again for the true running of the work.

Rotate the chuck by hand and observe the gap between

the pointer and work surface for the position of the two

opposite jaws.

Open the jaw slightly where the gap is more, and tighten

the opposite jaw. (Fig 5)

Repeat until the gap is the same. (Fig 6)

Repeat the above sequences for the other set of opposite

jaws.

Bring the pointer tip closer to the work surface.

Producltion & Manufacturing : Turner - Exercise 1.3.27 83