Page 97 - Turner 1st sem Practicals

P. 97

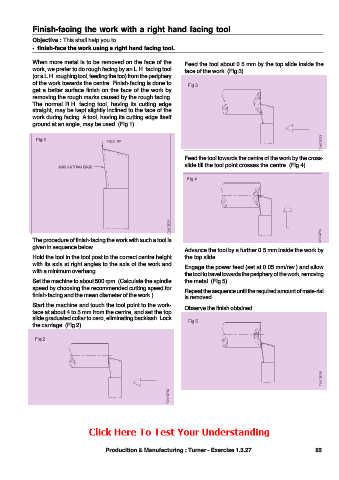

Finish-facing the work with a right hand facing tool

Objective : This shall help you to

• finish-face the work using a right hand facing tool.

When more metal is to be removed on the face of the Feed the tool about 0.5 mm by the top slide inside the

work, we prefer to do rough facing by an L.H. facing tool face of the work. (Fig 3)

(or a L.H. roughing tool, feeding the too) from the periphery

of the work towards the centre. Finish-facing is done to

get a better surface finish on the face of the work by

removing the rough marks caused by the rough facing.

The normal R.H. facing tool, having its cutting edge

straight, may be kept slightly inclined to the face of the

work during facing. A tool, having its cutting edge itself

ground at an angle, may be used. (Fig 1)

Feed the tool towards the centre of the work by the cross-

slide till the tool point crosses the centre. (Fig 4)

The procedure of finish-facing the work with such a tool is

given in sequence below.

Advance the tool by a further 0.5 mm inside the work by

Hold the tool in the tool post to the correct centre height the top slide.

with its axis at right angles to the axis of the work and Engage the power feed (set at 0.05 mm/rev.) and allow

with a minimum overhang.

the tool to travel towards the periphery of the work, removing

Set the machine to about 500 rpm. (Calculate the spindle the metal. (Fig 5)

speed by choosing the recommended cutting speed for Repeat the sequence until the required amount of mate-rial

finish-facing and the mean diameter of the work.)

is removed.

Start the machine and touch the tool point to the work- Observe the finish obtained.

face at about 4 to 5 mm from the centre, and set the top

slide graduated collar to zero, eliminating backlash. Lock

the carriage. (Fig 2)

Producltion & Manufacturing : Turner - Exercise 1.3.27 85