Page 60 - Turner 1st sem Practicals

P. 60

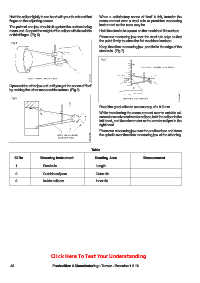

Hold the caliper lightly in one hand with your thumb and first When a satisfactory sense of ‘feel’ is felt, transfer the

finger on the adjusting screws. measurement over a steel rule or precision measuring

instrument as the case may be.

The point of one jaw should sit against the surface being

measured. Support the weight of the caliper with the middle Hold the steel rule square on the machined flat surface.

or third finger. (Fig 5)

Place one measuring jaw near the steel rule edge so that

the point firmly touches the flat machined surface.

Keep the other measuring jaw parallel to the edge of the

steel rule. (Fig 7)

Open out the other jaw and until you get the sense of ‘feel’

by rocking the other measurable surface. (Fig 6)

Read the graduation to an accuracy of ± 0.5 mm.

While transferring the measurement over to outside mi-

crometer or universal vernier caliper, hold the caliper in the

left hand, and the micrometer or the vernier caliper in the

right hand.

Place one measuring jaw over the anvil surface and close

the spindle over the other measuring jaw of the other leg.

Table

Sl.No Meauring Instrument Reading Area Measurement

1 Steel rule Length

2 Outside calipers Outer dia

3 Inside calipers Inner dia

48 Producltion & Manufacturing : Turner - Exercise 1.2.16